INTEGRATION OF LCA AND LCC IN DECISION PROCESS

Michal Biernacki, PhD. MSc. Eng.

Wroclaw University of Economics, Poland

|

Nowadays environmental management practices and attention are not focused only on addressing emissions and waste discharges to the environment from production processes, but they skip to products’ life cycles and their environmental impact. Environmental assessment tools such as Life Cycle Assessment and Life Cycle Costing are successfully applied by enterprises and research institutions to identify, analyze and calculate the environmental effects of a product through its life cycle Life Cycle Assessment is used usually for material based on its life cycle from cradle to grave. Life Cycle Costing is a calculation method that may help controlling cost of whole process and take environment and energy aspect into account The methodology of Life Cycle Assessment together with Life Cycle Costing offers the main starting point for global sustainability reporting including the emerging future trends in this context and its cost. The paper presents an overview of goals, scopes, framework of an idea of combination of results of integration of Life Cycle Assessment and Life Cycle Costing research. Keywords: environmental accounting, sustainable development, Life Cycle Assessment, Life Cycle Costing |

Introduction

Sustainable development is part of the survival of our global society. It could be defined as a development that meets the need of the present without compromising the ability of next generations to meet their own needs. Many firms are now expected to have an environmental management system in operational and strategic meaning to consider green aspects within the whole construction process. In order to understand how environmental thought and other related concepts become underlined and translated into physical objects in contemporary green projects, it is needed to have a grip of earlier and current flow of ideas (Baumann, 1998). The environmental decision is suggested to be similar to the general way of deciding proceeding in the company. It must be as a part of whole process of management.

1. Life Cycle Assessment – Definition and Methodology

Life Cycle Assessment understands a product that is followed from its “cradle” where raw materials are extracted from natural resources through production to its “grave”, the disposal (Baumann, 1998). The goal of LCA is to underlined those particular areas in the environmental profile of a product where producers should focus their reply in order to minimize their environmental impact.

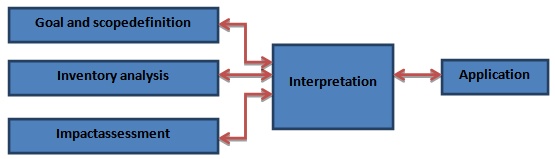

The Life Cycle Assessment system can be allocated into five successive phases; goal and scope definition, inventory analysis, impact assessment, result interpretation and application, (Figure 1).

|

| Figure 1. Methodology of LCA (Baumann, 2004 |

The LCA, in accordance with International Organization for Standardization (ISO) standard is a technique that aims at studying the environmental aspects and potential impacts of a product’s or process’s life cycle, starting at the raw materials extraction through the product manufacturing, until use and final disposal stages (ISO, 1997).

The LCA methodology applied ISO 14040, 14041, 14042 and 14043 (ISO, 1997; 1998; 2000a; b), which distinguish four phases in an LCA study: goal and scope definition, inventory analysis, impact assessment and interpretation. These system covers the product-related and life cycle view, taking into consideration up-and-down stream practices. It provides results on impact level which enable a focus on environmental effects and parameters.

However the main aim of Life Cycle Assessment is to guarantee complete and detailed identification of environmental effects of a product throughout its lifetime.

2. Life Cycle Costing – Main Scope

Life cycle costing (LCC) is a technique to estimate the total cost of ownership. The technique can assist decision‐making for all projects (Nelson 2002). LCC system is folded of three appraisal levels: strategic, system and detail. The strategic level is mainly for the initial evaluation stage in the pre‐construction phase. The system and detail stages are mostly used in the design stage. The assumptions made earlier are defined (Pulakka, 1999).

Life Cycle Costing is an economic calculation of an item, system or facility over its life, expressed in terms of equivalent cycle costing. It has an occasion to connect initial cost and ownership cost to optimize total cost of firms. The history of LCC has started in the Second World War when it was created, due to material and labor shortages. It is possible to identify two distinct option of life cycle costing:

- estimating costs on a whole life cycle basis;

- monitoring the cost incurred throughout a product’s life cycle (Biernacki, 2011).

This technique takes the investment costs and costs in operation of all phases into account. The full costs can be considered from varied points of view for example from the product’s supplier or the product’s user or from the point of view of society. Life Cycle Costing also could be understood as a technique of thinking and not only as a costing instrument because in addition to the management of costs. It focuses on the long-term performance of products by getting a variety of management accounting procedures. There is LCC is applied to quantifying costs of whole buildings, systems and building components and materials in the construction industry. The method can assist decision‐making for all projects.

3. Life Cycle Costing and Life Cycle Assessment

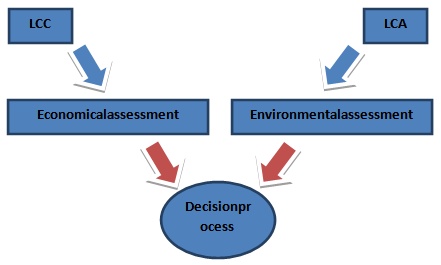

Life cycle costing and life cycle assessment measure cost and environmental performance of activity of every enterprise. However the assessments make study from two different scopes (nature science and social science).Both of these are very important in decision making process for product design and tender selection (Figure 2). It is an aim to find a possible way to include them together to accommodate both economic and environmental elements.

|

| Figure 2. LCC/LCA as tool for decision making process (Jae in 2006) |

The LCA and LCC methods are together life cycle technique tools. Furthermore, the time horizons of their research goals are the same. It means: from cradle to grave. On the other hand, both of these tools need to make calculations through getting data from the database. The LCA focus on the environmental impact in the future and LCC concerns on long term benefits.

The differences between LCA and LCC are unfortunately more obvious i.e.: data on the complete set of upstream processes are necessary for the calculation of the total environmental impact in LCA, while in LCC we speak about cost. It provides that the price can be sum up but the impact cannot. LCA system is top‐down, which means environmental impacts caused by chemical elements of materials are selected from different components of product. It is opposite to LCC method where it is bottom‐up. It means the total cost is sum up by cost of each step during the life cycle (Table 1).

| Table 1 |

| Comparison of LCA and LCC |

| Life Cycle Assessment | Life Cycle Costing | |

| Time horizon | Average life of products | Average life of products |

| Method | Quantity Top‐down | Quantity Bottom‐up |

| Focus | Future environmental impact Environmental impacts | Future economic value Economic value |

| Scope | Materials and products | Cost |

| Evaluated environmentalimpacts | Air, soil, water | Not considered |

| Costcalculation | Not considered | Totally system cost |

The easy way to link them together is to convert the LCA impacts intoamount-cost.Itsee thatboth the LCC and LCA variables are taken into account in quantifying the cost. According to Tupamaki:

LCC = Capital investment + NPV,

where NPV is based on:

- use and maintenance,

- operating cost,

- repairs + rehabilitation,

- salvage value,

- environmental LCA factors,

- occupational LCA factors,

- location LCA factors (Tupamaki, 2004).

In this formula above, environmental aspects refer to all the environmental impacts from materials and activities in the whole life cycle of every product. Moreover, the occupational factors goes to health, productivity and the other factor mean about people’s satisfaction. It must be underline that some hidden environmental costs cannot be calculated at whole. Another method incorporates environmental costs into LCA for making strategic and operating decisions on improving environmental performance and investment. The eco‐cost includes costs as below:

- of controlling gas emissions;

- of resources used and energy& water consumption in extraction and production of products;

- of waste disposal;

- of waste treatment, including solid waste and others;

- of eco‐taxes;

- of pollution rehabilitation measures;

- of environmental management (Arup, 2002).

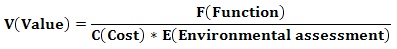

The integrated decision making tool includes both LCC and LCA can beused for selecting, suitable alternative. The formula is a below (Jaein, 2006):

|

In this method, managers use value engineering and LCC as an economic tools and LCA as an environmental assessment tool. Value engineering and LCC method will be used as first for economical part of the item and then LCA is applied to environmental aspect. Manager should consider two aspects simultaneously and same weight to choose the best alternative. The steps are as follows:

- Present alternative,

- Establish performance criteria,

- Calculate performance criteria matrix,

- Find function score,

- Calculate cost index,

- Calculate environmental score,

- Value analysis and selection (Jaein, 2006).

As it known, an environmental specific of a product is determined in design stage. With this concept, there are two segments join to each other in decision making process. One is design company which shows an key role in selecting the materials and designing structure. They can design and make alternatives and provide raw data to other firm. The other is consulting department (firm), which includes environment consulting company and economic consulting company, and it charges evaluation and feedback.

The other combination of these two methods is Environmental Life Cycle Costing which has been discovered by deficiencies of other practices as mentioned above.

4. Environmental Life Cycle Costing

Environmental Life Cycle Costing (ELCC) is a catalog of whole cost incurred during product cradle-to-grave cycle. Specific point of the ELCC model is the requirement that all cost under study have to be refer to actual monetary flow. The main reason of use of ELCC accounting is the reflection that standard methods of product life cycle assessment, such as Life Cycle Assessment, are often perceived as blockades to economic development. This is a mainly evident in relation to modern technologies, characterized by quick finish of life time cycle.

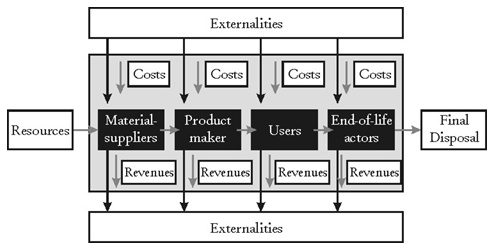

General structure of Environmental Life Cycle Costing is based on physical life cycle of a product. This method needs separate assessment of 5 distinct life time stages, detailed and elaborated as required: research and development, production, use and maintenance, and disposal/recycling management.

|

| Figure 2. Conceptual framework of Environmental Life Cycle Costing (Hunkeler, Lichtenvort, Rebitzer, 2008) |

Environmental Life Cycle Costing system, as contrasted to traditional Life Cycle Costing, supplements product cost analysis with the so-called environmental cost. The environmental cost represents economic cost incurred as a result of environmental use, such as eco-taxes, cost of waste emission and emission control, cost of eco-product marketing, etc.. These cost items should be inventoried and singled out in profit-and-loss account. Furthermore, it takes into accounting and bookkeeping all environmental cost supplemented by any external cost (Figure 2) (Hunkeler, Lichtenvort, Rebitzer 2008).

ELCC should not be implemented as an independent system but with connection with Life Cycle Assessment which is a globally normalized method for evaluation of environmental impact of a product as well as estimation of total consumption of resources within the complete product life cycle (Ciambrone, 1997).

Environmental Life Cycle Costing has to be done within the second stage of the LCA process, i.e. during input data inventorying as well as output data inventorying for individual processes and for selected functional units. Input data is a numbers of materials and energy use can be supplemented by cost data pertaining to each item. Output data taking into account emission and waste production data, one may supplement them with corresponding cost of economic use of environment. Both of them may be presented in monetary terms (Hendrikson, Lave, Matthews, 2006, 10).

Environmental Life Cycle Costing mentions to all cost incurred. The total cost is fragment of the system defined within the LCA part. Following this, the ELCC calculation may be formulated as formula showed below (this is a first expression and can be modified in accordance with requirements of a given entity and firm’s specificity).

ELCC = CIC + CIN + CE + CO + CM + CS + CENV + CD ,

where:

CIC – initial investment cost

CIN – installation cost

CE – energy cost

CO – operational cost

CM – cost of repairs and maintenance

CS – cost of stoppages and production losses

CENV – additional environmental cost

CD – cost of recycling, discharge, rehabilitation (Kowalski, Kulczycka, Góralczyk, 2007).

Conclusion

Environmental Life Cycle Costing is a modern tool for reporting on companies’ efforts in the field of sustainability development. This method can be used by companies for marketing purposes, to communicate with shareholders, stakeholders, government and clients. The trends in terms of the analysis of corporate and environmental friendly sustainable development are moving towards:

- product-related analysis;

- inclusion of indirect effects via the life cycle approach;

- analysis on impact level;

- automation of data administration.

The methodology of life cycle assessment linked with life cycle costing provides the main starting point for global sustainability reporting, as the Environmental Life Cycle Costing. The LCA and LCC methods covers the product-related and life cycle view, taking into consideration upstream and downstream processes. Based on the LCA, LCC and ELCC techniques some enterprises turn to manage using life cycle. Life Cycle Management (LCM) in a simple words is a derivative of Life Cycle Costing and Life Cycle Assessment. In a simply way, it identifies those areas in which running costs detailed by Life Cycle Costing might be reduced by a change in operating, planning practice and sometimes the appropriate system with environmental impact as well.

Bibliography

Arup company (2002). Report on Life cycle assessment and life cycle costing for commercial building development in Hong KongHong Kong

Biernacki M (2011). Rachunek kosztów cyklu życia – ujęcie definicyjne i obszarowe Prace Naukowe Uniwersytetu Ekonomicznego we Wrocławiu pod red. E.Nowak, M.Nieplowicz “Rachunek kosztów I pomiar dokonań” nr 182, UE,Wrocław, 2011, pp.36–45

Ciambrone D.F.(1997). Environmental Life Cycle Analysis Lewis Publisher, New York, pp.6–9

European Committee for Standardization (1997). EN ISO 14040: Environmental Management – Life Cycle Assessment – Principles and Framework, European Committee for Standardization, Brussels

European Committee for Standardization (1998). EN ISO 14041: Environmental Management – Life Cycle Assessment – Goal and Scope Definition and Life Cycle Inventory Analysis, European Committee for Standardization, Brussels

European Committee for Standardization (2000a). EN ISO 14042: Environmental Management – Life Cycle Assessment – Life Cycle Impact Assessment, European Committee for Standardization, Brussels

European Committee for Standardization (2000b). EN ISO 14043: Environmental Management – Life Cycle Assessment – Life Cycle Interpretation, European Committee for Standardization, Brussels

Hendrikson C.T., Lave L.B, Matthews H.S. (2006). Environmental Life Cycle Assessment of Goods and Services. An Input and Output Approach RFF Washington pp.6–8

Henrikke Baumann (1998). Life cycle assessment and decision making: theories and practices, Technical environmental planningSweden

Hunkeler D., Lichtenvort K., Rebitzer G. (2008). Environmental Life Cycle Costing CRC Press SETAC, pp.9–16

Jaein Ha and Taisik Lee (2006). Integrated economical‐environmental decision‐making on waste water treatment plant construction project, Korea

Kowalski Z., Kulczycka J., Góralczyk M. (2007). Ekologiczna ocena cyklu życia procesów wytwórczychWydawnictwa Naukowe PWN, Warszawa, 170–178

Nelson A (2002). Sustainability, new technologies and life‐cycle costs, Stanford University, USA Pulakka S (1999), Life‐cycle cost design methods and tools, Durability of building materials and components, Espoo, Finland

Tupamaki, O. (2004). Post Occupation Evaluation – POE Villa Real Ltd/SA